plastic tube thickness gauge can measure the thickness of multi-layer pipe

Description

The plastic tube thickness gauge is a kind of ultrasonic testing

system in pipe extrusion that is mainly used to do uninterrupted online

real-time measuring and monitoring of the change of the thickness,

outer diameter, eccentricity and out-of-roundness in the whole

production process of plastic pipes.

Advantages

1. The measurement accuracy and stability

Our plastic tube thickness gauge adopts the patent technology of

automatic capture and USA high-precision probe, which make the

measurement data more stable and more accurate.

2. Automatic identification and marking of pipes

You can know everything about production in any time without

reading production records written by workers in the production process,

since our ultrasonic testing system in pipe extrusion can monitor and

record the whole pipe production process. By the automatic

identification and marking function, the user can easily know about the

production and quality conditions. In case that the quality risks of

pipes are found, you just need to go to the warehouse and find out the

numbered pipes. Even if the problem pipes have been carried to the

construction site, we can also find them out, because the recording and

filing dates of our system can be traced back to half a month, even half

a year ago.

3. Imported parts

The high precision ultrasonic transducer, signal processor, cable

and other core measurement parts for this plastic tube thickness gauge

are all imported from America which ensure the measurement more stable

and prolong the service life.

4. Imported ultra-thin industrial control tablet computer

In order to ensure comprehensive and real-time data, our ultrasonic

testing in pipe extrusion adopts independent industrial tablet and

large capacity hard disk to do the high speed and large capacity data

storage to prevent the data of unqualified pipe to be left out.

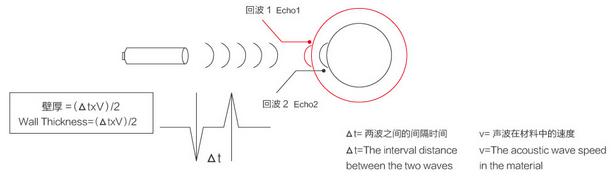

Working principle

The measurement principle of probe is as following:

The ultrasonic probe distribution structure is as following:

1. The built-in fixed ultrasonic transmitter can measure various range of pipe wall thickness.

2. The number of ultrasonic probe: 4, 8, 16

3. The protection grade of the ultrasonic probe is IP68, thus it

can be directly fixed to the scanning box, and whole installed inside

of the water tank (determined on specific model).

4. The probe of the plastic tube thickness gauge can measure the

thickness of multi-layer pipe, and the thickness of each layer can be

displayed separately (optional).

Specifications

Probe: ULTRAMAC 160-8T

Measurement range of external diameter: 32-160mm

Installation

This kind of plastic tube thickness gauge is usually installed behind the first vacuum box.