- Gravimetric Control System

- Ultrasonic Thickness Measuring System

- Gravimetric Blending&Feeding System

- Gravimetric WBB-H Series Batch Blender

- Gravimetric Continuous Blender

- Powder Feeding Machine

- Loss-in-Weight Side Feeder

- Gravimetric WBB-S Series Batch Blender

- Material Conveying System

- Vacuum Autoloader

GMS-20 control system for plastic extrusion

Description

The quality control system for plastic extrusion is mainly used

in the extrusion production line to control and maintain a consistent

weight or thickness of extruded product.

Application

This kind of gravimetric controller is suitable for controlling the production line of plastics pipe, plastic film, etc.

Easy operational interface with rich functions can fully meets any production measurement requirements. Displayer Control Unit (three configurations of I, II and OEM are available)

Advantages

1.Now this equipment is suitable for all kinds of extrusion production lines and control methods in the world.

2.Because this quality control system for plastic extrusion takes dedicated arithmetic, so it has higher control accuracy and corresponding speed.

3.The control precision is 3‰, and it is far higher than competitor's 4‰.

4.Our gravimetric controller can simultaneous control the weight per length and extrusion output, which breaks the limit of this industry that only control weight per length or extrusion output and contribute to efficient control of production line. Our control system is particularly suitable for the extruder with unstable extrusion output that caused by a variety of factors. Even there are application cases to prove that our equipment can control the production line that is on the edge of scrapped and produce qualified tubular product. Thus bring big benefit for the customer.

5.Our quality control system for plastic extrusion can save 4-5 times material than competitor for it only needs a few minutes to start and function.

6.We provide one year warranty and life-long software free update services. Also we offer 24 hours service to ensure your normal production. With high quality and excellent after-sale service our product gets consistent high praise.

installation

This gravimetric controller is installed on extruder's

feeding inlet which instead of storage hopper and accurately control the

required material per hour, and the required material per length to

ensure user produce qualified products with short starting time and low

labor cost.

Installation Description

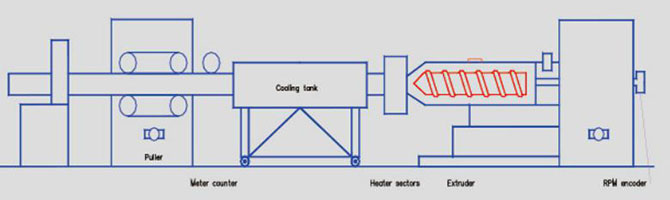

The original extrusion production line

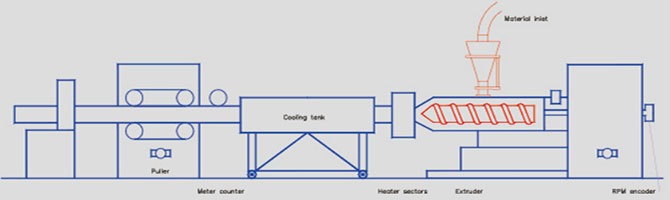

Remove the storage hopper

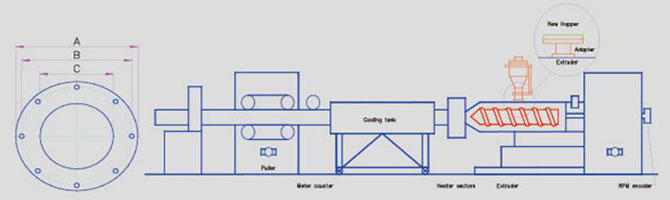

Make an adaptor and then install the gravimetric controller

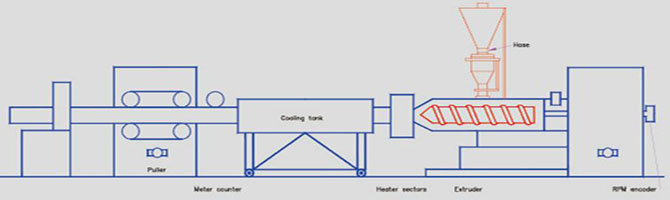

Install stand and storage hopper on this equipment

Specification

| Model | Output | Size |

| GMS-04 | Up to 60 | 350×310×620 |

| GMS-06 | Up to 200 | 360×350×715 |

| GMS-08 | Up to 350 | 395×372×810 |

| GMS-12 | Up to 450 | 395×372×880 |

| GMS-20 | Up to 700 | 530×468×920 |

| GMS-30 | Up to 900 | 530×490×960 |

| GMS-50 | Up to 1200 | 530×551×1080 |

| GMS-80 | Up to 1600 | 530×582×1460 |