- Gravimetric Control System

- Ultrasonic Thickness Measuring System

- Gravimetric Blending&Feeding System

- Gravimetric WBB-H Series Batch Blender

- Gravimetric Continuous Blender

- Powder Feeding Machine

- Loss-in-Weight Side Feeder

- Gravimetric WBB-S Series Batch Blender

- Material Conveying System

- Vacuum Autoloader

GMS-50 gravimetric control system for plastic extrusion line

Description

The GMS-50 gravimetric control system for plastic extrusion line

is installed on an extruder to measure and calculate the weight per

length and extrusion output, and also do an automatic control, which

make the product with constant weight per length and(or) extrusion

output and the extruder run at preset values.

Accuracy Error

The precision error is less than 0.3~0.5% (differs from the different raw materials and machines)

Application Pictures?

How It Works?

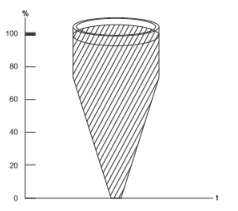

Picture1: The material starting-up status. The GMS-50 gravimetric control system for plastic extrusion line is installed between the material storage hopper and the extruder throat. It monitors the loss in weight of the material in its weigh chamber and from this calculates the mass throughput rate of the extruder. In auto control mode our product can control the extruder or the production line speed to maintain a set output or a set product weight per unit length.

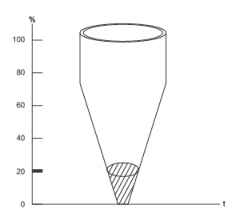

Picture 2: While the material reduces little by little, the system will do the real time measurement of per-meter weight and extrusion output continuously.

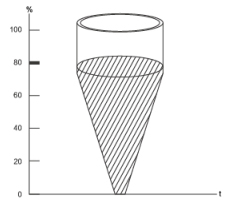

Picture 3: When the weight of material in the weigh chamber falls below a preset value, a slide valve will open and refill the chamber from the material storage hopper. Then a new measurement and control process begin

Advantages

Shorten startup time

The operator simply need to connect the product (like the

pipe) and do the normal pulling, then the GMS-50 gravimetric control

system for plastic extrusion line could automatically adjust the product

meter weight to a qualified range, which will break away from the

dependence on the experience and skill of operators.

The system monitor the weight per length of product in the whole production process, and collect the data of weight per length in real-time. If deviation was found, it will immediately adjust the extruder or the puller to reach the stable weight per length and make it running according to the preset value.

3. Alarm systemOur GMS-50 gravimetric control system for plastic extrusion line with product deviation alarm: the prompt reminder of alarm information for the product quality risk that appears will effectively prevent product quality defects.

4. Cost savingOur device not only saves the cost of raw material and labor but also reduces the unqualified products. Before using our equipment, the worker needs to adjust the extruder several times in the startup process by their rich experience. In this period it will lead to a lot of waste for producing unqualified products and at the same time the user will pay much more money to employ experienced worker. After equipped with our device, the worker only needs to set the value of weight per length and extrusion output per hour to realize the automatically control and make the extruder produce qualified products.

5. High qualityWith strict quality control and good performance, our GMS-50 gravimetric control system for plastic extrusion line gets the CE certificate and occupies the leading position in this area no matter in appearance, technology and sales volume.

6. Service advantageWe provide one year warranty and life-long free software update services. Also we offer 24 hours service to ensure your normal production. With high quality and excellent after-sale service our product gets consistent high praise.

Specifications

| Model | Output | Size |

| GMS-04 | Up to 60 | 350×310×620 |

| GMS-06 | Up to 200 | 360×350×715 |

| GMS-08 | Up to 350 | 395×372×810 |

| GMS-12 | Up to 450 | 395×372×880 |

| GMS-20 | Up to 700 | 530×468×920 |

| GMS-30 | Up to 900 | 530×490×960 |

| GMS-50 | Up to 1200 | 530×551×1080 |

| GMS-80 | Up to 1600 | 530×582×1460 |