- Gravimetric Control System

- Ultrasonic Thickness Measuring System

- Gravimetric Blending&Feeding System

- Gravimetric WBB-H Series Batch Blender

- Gravimetric Continuous Blender

- Powder Feeding Machine

- Loss-in-Weight Side Feeder

- Gravimetric WBB-S Series Batch Blender

- Material Conveying System

- Vacuum Autoloader

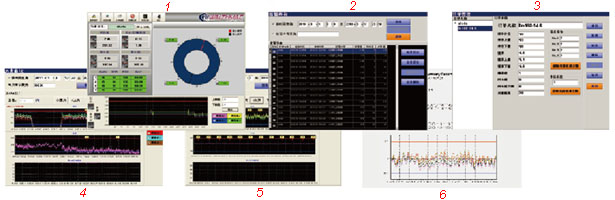

Ultrasonic Thickness Measuring System

1. Application scope: gas pipe, water supply pipe, catheter and medical catheter.2. Used for the uninterrupted measuring and monitoring for the change of thickness, outer diameter, eccentricity and out-of roundness in the whole production process of pipes, therefore, the quality risks can be completely eliminated in production.

The System Brings the Following Benefits

1. Lower and completely eliminate the quality risks in the production of plastic pipes and improve product quality .2. Shorten the start-up time, reduce rejection ratio.

3. Function of complete recording and filing of production data.

4. Automatically generate pipe quality statistics form.

The Advantages Differs from the Traditional Ultrasonic Thickness Measurement System

1. Accuracy and StabilityThe measurement data is more stable and accurate by the adoption of automatic capture patent technology and high-precision probe with the best technology.

2. Automatic identification and marking of pipes

You can know everything about production and quality anytime without reading production records written by workers in the production process, since our measurement system can monitor and record the whole pipe production process. By the automatic identification and marking function, the user can easily know about the production and quality conditions, in case that the quality risks of pipes are found, you just need to go to the warehouse and find out the numbered pipes. Even if the problem pipes have been carried to the construction site, we can also find them out, because the recording and filing datas of our system can be traced back to half a month, even half a year ago.

3. Convenient for production management

System measurement data cover the whole production process, and you can easily know about the followings: shutdown time of production line, starting time of production line, quality problem occurring time, etc.

4. Quality statistics of single pipe

Our system can generate a quality statistical report for every pipe to meet the strict quality requirements form high-end customers, and the report can be printed out as an effective evidence, for your pipe quality.

5. Our remote monitoring software can let you easily know about the production field and the historical production datas.(optional)

6. The patented handheld remote terminal technology helps workers to operate the machine remotely.(Optional)

Main Functions

1. Real time measuring wall thickness and pipe OD

2. Automatically alarm when exceed the pipe tolerance error and store the alarm information list

3. Used for setting and managing the production formulas and orders

4. Positioning quality problems-by analyzing the historical production curves

5. Marking function-tracking the pipe movement

6. Automatically generate a quality statistical report, and the report can be printed out

Features

1. All key parts are with the highest standard technology .2. The highest measurement precision can reach to 0.001mm, the minimum measurable OD:0.25mm, the maximum measurable OD:1600mm

3. Low consumption of measured power(<30w)

4. The production measurement historical data recording can be stored for a long time

Optional Items

1. Automatically number the pipes that come off the production line, identify and number the waste pipes2. Automatically generate quality statistical report for every pipe.

3. Remote monitoring

4. Measurement of multi-layer pipes

The Ultrasonic Signal Processor DSP (The Ultrasonic Auto-capture Technology of USA Patent)

Main Functions

1. Automatic search:DSP can quickly find out the right echo and distinguish clutter.

2. Automatic setting ;

DSP can search the right echo and automatically adjust signal gain according to preset parameters.

3. Automatic tracking:

When the product changes ,DSP can instantly adjust the capture window so as to track and lock the right echo.

4. Highest precision:

The capture and calculation of all exhoes by DSP are automatical. These processes like scanning , capturing , adjustment , measurement and calculation always keep consistent with the change of products and setting . Therefore , higher precision of average wall-thickness and concentricity can be realized.

5. Without human intervention: providing unique self-setting technology.