Material Conveying System

For the first step of factory automation, MTS centralized material conveying system achieves material concentrated storage and supply instead of separated transportation one by one. The cost of energy and labour is reduced effectively and an expected standard, tidy and ordered production site comes true.

System Application

The MTS system can provide many sets of equipments controlled with one conveying device for multi extruders centralized conveying of multi components. The workshop is separated from raw material transportation to reduce the dust and noise.

Advantages

1. The whole conveying process of the system works in a fully-enclosed condition to prevent secondary pollution in the transport.

2. Automatic centralized deducting devices effectively prevent pipe from blocking.

3. Realize remote and higher occasion conveying.

4. Effectively reduce the workshop noise.

5. Lower energy consumption and labor cost.

6. Automatic loading/filing and detection of material lacking.

7. Stable and reliable performance assured by imported core components.

8. Company image effectively improved for the high-level automation.

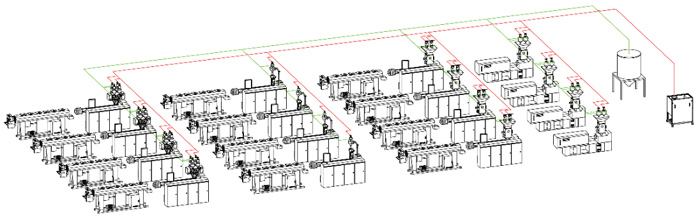

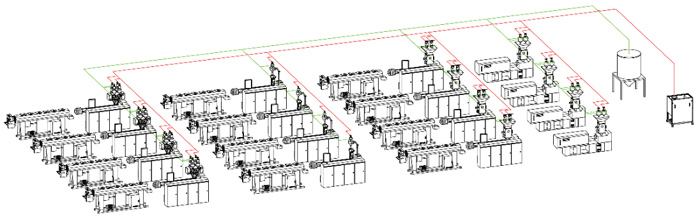

MTS Centralized Conveying System Schematic

Note:

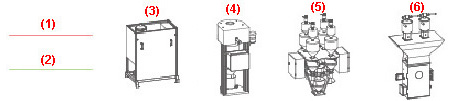

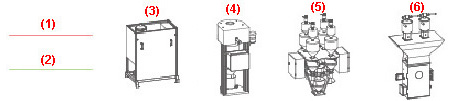

(1) Vacuum Conveying Pipe

(2) Material Conveying Pipe

(3) Material Conveying System

(4) Online Gravimetric Control System

(5) High Precision Gravimetric Continuous Blender

(6) High Precision Gravimetric Batch Blender

Parameter

The model with ACE means having the

automatic dust removal device.

1:conveying by blower

2:converying by vacum pump.