Online thickness measurement system can remind workers to adjust the production line quickly

Description

The online ultrasonic thickness gauge for plastic tube is used for

the uninterrupted online real-time measuring and monitoring of the

change of the thickness, outer diameter, eccentricity and

out-of-roundness in the whole production process of tubular products

(like gas pipe, water supply pipe, conduit pipe, medical catheter,

etc.). The warning function of the online thickness measurement can

remind workers to adjust the production line quickly to ensure the

product quality and also the quality statistics report can be printed

out for users.

Advantages

1. Automatic identification and marking of pipes

You can know everything about production any time without reading

production records written by workers in the production process, since

our online ultrasonic thickness gauge can monitor and record the whole

pipe production process. By the automatic identification and marking

function, the user can easily know about the production and quality

conditions. In case that the quality risks of pipes are found, you just

need to go to the warehouse and find out the numbered pipes. Even if the

problem pipes have been carried to the construction site, we can also

find them out, because the recording and filing dates of our system can

be traced back to half a month, even half a year ago.

2. Remote monitoring software

Our patent hand-hold remote monitoring technology of the online

thickness measurement system can makes worker remotely operate the

machine and also make worker know the present and historical situation

of the production line.

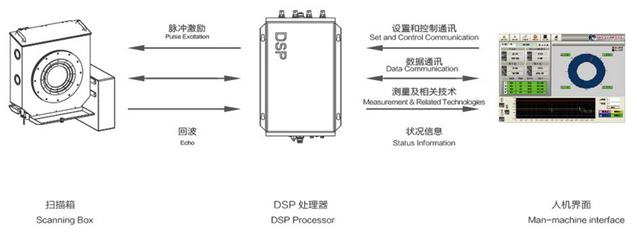

Structure

This kind of online ultrasonic thickness gauge is mainly composed

of scanning box, DSP signal processor, industrial personal computer and

other hardware.

Specifications

Probe: ULTRAMAC 630-4T

Measurement range of external diameter: 250-630mm