- Gravimetric Control System

- Ultrasonic Thickness Measuring System

- Gravimetric Blending&Feeding System

- Gravimetric WBB-H Series Batch Blender

- Gravimetric Continuous Blender

- Powder Feeding Machine

- Loss-in-Weight Side Feeder

- Gravimetric WBB-S Series Batch Blender

- Material Conveying System

- Vacuum Autoloader

ultrasonic online thickness measuring system of plastic pipe

Description

Our ultrasonic online thickness measuring system of plastic pipe

is based on the principle of ultrasonic non-destructive measuring which

adopts the automatically capture and setting technology of ultrasonic

waves to do real time angle and orientation's adjustment algorithm, data

communication, field data collection, multiple control algorithm,

database access, etc. Thus, it provides a perfect production testing

method for users who want to save the consumption of raw material and

labor. It efficiently reduces the accident of plastic pipe blow out

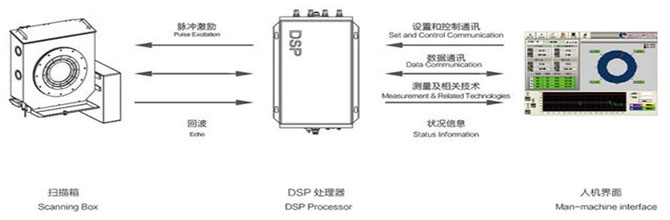

caused by the quality problems . This thickness measurement system is

composed of scanning box, DSP signal processor, industrial personal

computer and other hardware structures.

Advantages

1. New technology

Ultrasonic online thickness measuring system of plastic pipe is strict with measuring media (water). Based on this defect, our company makes a great improvement of the structure design for that we developed a scanning box with purge function for our thickness measurement system. This special purge structure design makes the bubbles automatically emanate from the water and do not float on the surface of probe , therefore, the result of the measurement won't be affected by bubbles. Our scanning box is a new technology of independent patent work with the performance of strong adaptation.

2. Long service life

The structure of water inlet and water outlet ensure the utilization of circulating water in scanning box, the clean inner space of scanning box, and also make sure the impurity will not stay in the scanning box for a long time , which highly prolong the service life of probe.

3. Automatic positioning system for unqualified pipe

We developed automatic positioning system for our ultrasonic online thickness measuring system of plastic pipe to find out the unqualified tubular product after producing, thus eliminate the quality risks in the production of plastic pipes and improve product quality. Our company add the software and hardware of data collection, location, and database query function on this system which make the unqualified pipe can be find out after production. The longest search time of the application can trace back to six months ago that is completely beyond the foreign and highly improve the market share.

4. Wide range transducer frequency

The transducer frequency is 0.5-20MHz that is suitable for measuring different pipes with the performances of high measurement accuracy and high measurement speed.

5. Comprehensive measurement

Our ultrasonic online thickness measuring system of plastic pipe doesn't need to move the probe to do the comprehensive measurement for different diameter pipe which is superior to imported product.

6. High measurement speed

Our original technology combined with ultrasonic processor that has the performance of high sensibility can make the measurement of linear velocity up to 100m/min.

7. Widely use

The measurement expands from single PE and PVC pipe to PERT, PP and all of other materials. So it is suitable for all the areas of the tubular product (like gas pipe, heating pipe, drain-pipe, etc.)

8. The power dissipation of measurement is less than 30w.

9. We promise customer to response and solve the problems in the using process within 24 hours.

Specifications

Probe type: US1012

Measurement range of external diameter: 0.25-12mm

Installation

Our ultrasonic online thickness measuring system of plastic pipe

is usually installed behind the first vacuum box thus can save the

correction time for unqualified pipe.