- Gravimetric Control System

- Ultrasonic Thickness Measuring System

- Gravimetric Blending&Feeding System

- Gravimetric WBB-H Series Batch Blender

- Gravimetric Continuous Blender

- Powder Feeding Machine

- Loss-in-Weight Side Feeder

- Gravimetric WBB-S Series Batch Blender

- Material Conveying System

- Vacuum Autoloader

GMS-06 Plastic Extrusion Weighing System

Description

Plastic extrusion weighing system by automatically controlling

and measuring the extrusion production line to make product have

constant weight pre length that we presetting before. It is suitable for

measuring and controlling the production of plastics pipe, thin film

and other plastic products (PE, PP, and PVC).

Materials

Plastic extrusion weighing system is suitable for measuring the

material of granule, rubber), powdery, mixture and untreated raw

material with the good performance of mobility.

Application

Easy operational interface with rich functions can fully meets any production measurement requirements.

Display Control Unit of the Gravimetric System (three configurations of I, II and OEM are available)

How It Works?

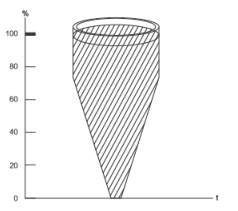

Picture1: The material starting-up status.

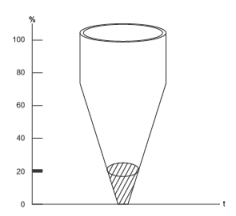

Picture2: While the material reduces little by little, the plastic extrusion weighing system will do the real time measurement of per-meter weight and extrusion output continuously.

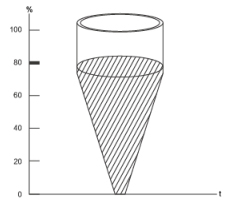

Picture 3: When the weight of material in the weigh chamber falls below a preset value. a slide valve opens and refills the chamber from the material storage hopper. Then a new measurement and control process begin

Advantages and Why Choose Us

1. Wide applications

Gravimetric system is suitable for all the extrusion production lines and all control modes in the world.

2. High standard

We produce the products according to the concept of "Products is also an artwork".

3. High accuracy and response speed

Our plastic extrusion weighing system adopts the dedicated algorithm to make it have higher precision and response speed.

4. High system stability

We are well aware that no need for service is the best service, and the stability of product has been put on the first place of our design and improvement.

5. Continuous upgrading

Innovative power and perfect pursuing for products help us to do the incessant upgrading for products. Based on the strong R & D capabilities of our two R & D centers, we promise to provide the users free lifetime upgrading service of product software.

6. Worry-free after-sales service

We are a professional gravimetric system supplier in China who have many offices and agents in domestic and overseas market, which will provide you quick and effective service.

7. Higher cost-effective and longer payback period of product investment

All parts of our plastic extrusion weighing system adopt best technology to ensure a longer life. And the rapid response speed will help customers save cost.

8. Extrusion system from several excellent extrusion equipment manufacturers integrated this system.

9. Gravimetric system is exported to many countries and regions.

Specifications

| Model | Output | Size |

| GMS-04 | Up to 60 | 350×310×620 |

| GMS-06 | Up to200 | 360×350×715 |

| GMS-08 | Up to 350 | 395×372×810 |

| GMS-12 | Up to 450 | 395×372×880 |

| GMS-20 | Up to 700 | 530×468×920 |

| GMS-30 | Up to 900 | 530×490×960 |

| GMS-50 | Up to 1200 | 530×551×1080 |

| GMS-80 | Up to 1600 | 530×582×1460 |