pipeline thickness testing system for plastic extrusion production line

Description

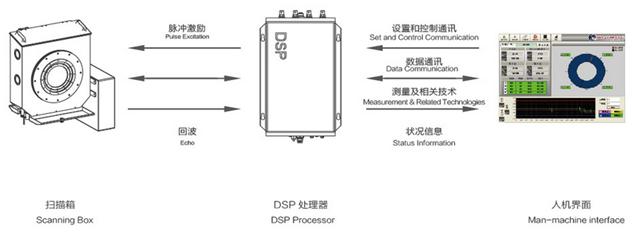

This pipeline thickness testing system is composed of scanning,

DSP signal processor, industrial personal computer and other hardware.

Scanning Box

The scanning box is equipped with ultrasonic measuring probe inside

and also has a cooling and purging device for probe. The ultrasonic

probe converts DSP signal processing pulse incentive energy into

ultrasonic wave and sends it out, and then convert echo small signals

into weak electricity signals and sends it back to the DSP signal

processor.

Main Function of DSP Signal Processor

1.Automatic search

DSP of pipeline thickness testing system can quickly find out the echo and then adjust the capture window accordingly.

2.Automatic setting

DSP for measuring system for pipeline can read the pattern of ultrasonic wave and find out the right echo.

3.Automatic tracking

When the product changes, DSP can instantly adjust the capture window so as to track and lock the right echo.

4.Highest precision

DSP of pipeline thickness testing system can automatically

capture and calculate all echoes internally, which really realize a

series of processing processes such as full-automatic scanning,

capturing, adjustment, measurement and calculation, and always keep high

consistency along with the changing of products and settings,

therefore, can provide higher precision measuring values of average

wall-thickness and concentricity.

5.Without human intervention

DSP for measuring system for pipeline can provide unique automatic setting technology.

System Structure

Man-machine interaction (MMI) - display control hardware and software

The DATASE-15H industrial tablet computer with DATASE1000R

ultrasonic measurement control software is configured, which is used as

the tool of data interchange, data acquisition and data storage. It uses

the high-end 12 or 15-inch TFT color touch LCD screen. The whole

pipeline thickness testing system adopts the ultra-thin and no fan

structure with light weight and good heat dissipation; therefore, it can

be used in a continuous operation environment with dusty, high

electro-magnetic interference and high ambient temperature. The

measuring system for pipeline has a large-capacity hard disk which can

store production data for a long time.

Specifications

Probe: ULTRAMAC 063-4T/2

Measurement range of external diameter: 3.75-63mm

Installment

Our pipeline thickness testing system is suitable for extrusion

production line, which is usually installed behind the first vacuum box

and can efficiently save the correction time of unqualified pipe.